Model : CPCD20/ 25/ 30/ 35-WS1H/ W4H

Rated capacity : 2.000-3.500 (kg)

Max.Lifting height : 3.000-7.000 (mm)

Transmission : 2-speed automatic electric

Engine model : ISUZU C240/ 4JG2

Rated power : 35.4/ 46 (kW)

Tire : Pneumatic/ Solid tires

Fork size : 1.070/ 1.220/ 1.520/ 1.820 (mm)

Delivery : 01-02 days

100% new imported equipment, never used.

Heli diesel forklift H3 series is proudly launched adhering to the principle of repaying the society with high quality product and vision of being century-old enter prise. To HELI, the H3 series is the culmination and milestone in pursuit of mastery in the development and manufacture of forklift over the years.

Elaborately built H3 series will provide you high level driving experience with environment friendliness, outstanding comfort, safety and reliability, easy maintenance and excellent working efficiency.

A. Environment-friendliness

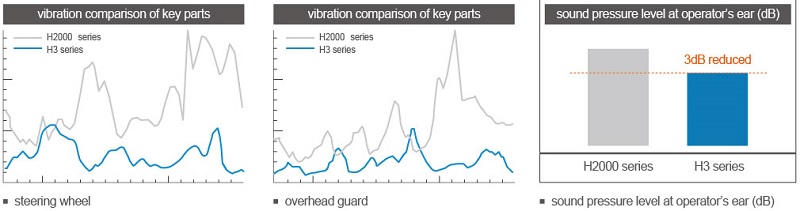

Clean and environment-friendly power meeting international emission standard is assembled on the H3 series to reduce harmful emissions and be environment-friendly. Meanwhile, H3 series effectively reduce truck vibration and noise. Compared with H2000 series vibration is reduced by more than 30% and the noise around ear is reduced by 3dB.

Comparison of vibration and noise of H3 series and H2000 series

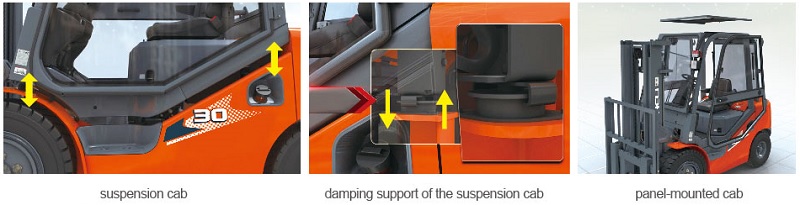

A.1 Suspension cab

Cushion connection between the frame and cab and wholly suspension cab absorb whole truck's vibration effectively. Fully-dlosed panel-mount-ed cab isolates the noise.

Completely separate chassis cabin system reduces vibration in H3 series

A.2 Suspension foot pedal

It isolates the vibration transmitted from the chassis to the operating devices No opening on the floor board improves the sealing performance and isolates chassis noise

A.3 Mast lowering buffering device

It reduces shock and vibration to the mast and avoids crash noise caused by goods falling to the ground.

A.4 Fully-closed cab

Fully-closed cab, using of thick sealing materials and acoustic material on the engine hood reduce the noise.

During the development of H3 series, we attached importance on improving driving comfort. Ergonomic designs, optimized operating device structure and layout improve driving experience and ensure long hours of efficient operation.

B.1 Enlarged operating space

Tilting cylinder located below the floor board, 30mm widened low anti-skidded slep and 45% enlarged operation space at foot provide comfort entry, exit and operation.

80mm heightened overhead guard and large arc shape of the overhead guard's front leg enlarge operating space and reduce operating fatique.

Closed cylinder shock absorber lifting frame expands driving space on H3 series

B.2 Semi-suspension seat

It reduces the transmission of vibration. The seat can adjust forward and backward to fit different operators' need.

B.3 Outstanding visibility

With three-stage free lift mast, front view width is increased by 30mm, with 15mm lowered instrument panel, the visibility of fork and goods is increased by 20mm. CAE optimized counter weight structure improve rear view.

Wide angle suspension seat with light steering wheel for easy operation

B.4 operator-friendly steering wheel

Automobile type combined switch, 60mm to 300mm reduced steering wheel diameter and optimized vertical distance between the steering wheel and operating knob make operations easy and quick and reduce 10% of the driver's left shoulder fatique High installed adjusting mechanism of the steering column is easy for operation and satisfies different operators.

B.5 LED combined instrument

With the clear displaying and right installment of the instrument, the operator can know the truck information in time

B.6 Rear assist handle (optional)

The assist grip wilh a horm enhances comfort by offering easy hom operation while travelling in reverse.

HELI keeps improving truck safety and reliability to ensure the safety of people, machine and goods.

Safe and reliable lifting and lowering system

C.1 Improved cooling performance

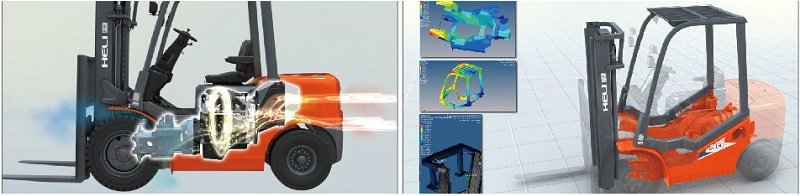

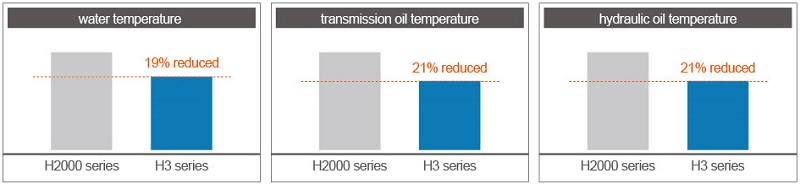

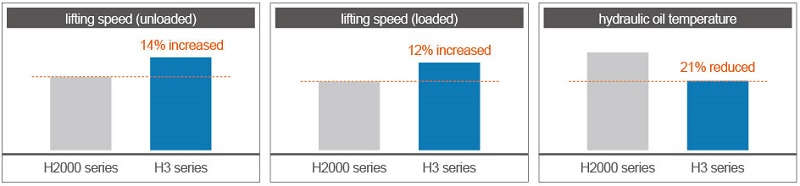

The hot air reflow isolating device, aluminum plate-fin type radiator, 60mm backward muffier and optimized thermal dissipation duct improve cooling ability and ensure engine work reliability to meel the requirements of working under harsh and high temperature envronment better. Compared with the truck with same capacity of H2000 series, the water temperature is 19% recuced transmissson oil temperature 21% reduced and hydraulic oil temperalure 21% reduced.

Improved cooling performance from H2000 series to H3 series

C.2 Key parts

The optimal design of key parts like frame, mast and overhead guard improve the whole truck's safety and reliability.

C.3 Fully-closed panel-mounted cab

Fully closed panel-mounted cab with high strength ensures the safety of people and machine fully.

C.4 Casting axle

The key rolation parts are protected from water and dust to extend their maintenance period. With the using of casting axle, the bcanng load carrying ability is improved and the truck structure is simple and reliable The service life is prolonged.

Ratchet parking brake with automotive style oil cap elastic foot pad

C.5 Ratchet type parking brake

Different braking force can be achieved on slope and flat ground. The brake is safe and reliable.

C.6 Automobile type oil adding cap structure

The cap use screw to protect it from loose and its stricture is simple

C.7 Double-lip elastic sealing gasket

The innovative design solves the problem of ol seang compictely

C.8 Hight installed rear combined LED lights

It is enorgy saving and stnking It effectively solves the problen of lights short service life and laripshade mell phenomanon It extends light sorvice life.

Easy maintenance which is good for maintaining the optimal condition of key parts and completed truck and ensures safety and work efficiency is the necessary character of a good product.

Brake fluid radiator hydraulic hose layout easy to disassemble and maintain

D.1 Large engine hood opening angle

Engine hood lock integrated on the hood is convenient for opening and close dunng mainte nance.

The gas spring has optimized arrangement prolonged gas spring service life and improved opening comfort 80 engine hood opening improved load carrying ability, opening angle, angle offers wide operation space for check and maintenance.

D.2 Front and rear floor board

It is easy to be disassembled and assembled and is easy to maintain engine and transmis-sion system

D.3 Compositional radiator heat flow baffle

It is connected with bolts and can be disassembled without disassembling counter weight

D.4 Brake liquid reservoir

Remove the upper cover of the instrument panel to observe the brake liquid level and add if necessary.

D.5 Optimized mast pipeline

Oil return pipelines are fixed onto the middle beam wih skid mounted clamp It is easy to install maintain and is good for oil retuming.

With high efficiency, the truck guarantees the material handling work at port, dock, and railway station. It can meet the requirements for various kinds of complicated work conditions.

E.1 High stability

With lowered and backward center of gravity, truck stability is 5% improved and thus the truck is more stable during loading and unloading and travelling Through optimizing the key parts, the truck loading capacity is 5% improved.

E.2 Quick responding steering wheel

With 100% pivot steering and retuming, the truck has good maneuverability in narrow space.

The truck has small tuming radius, easy steening, good gradeability and flexible maneuverability.

E.3 Constant load sensing steering system

It increases lifting speed, reduces hydraulic oil temperature, improves working efficiency and extends seals service life.

Compared with the truck with same capacity of H2000 series, the lifting speed without load is 14% improved, the lifting speed with load 2% increased and the hydraulic oil temperature is 21% reduced.

Lifting speed is improved from H200 series to H3 series increased

Actual images of Heli 3-ton, 3.5-ton diesel forklifts, H3 series

3 ton diesel forklift H3 series model CPCD30-WS1H

3.5 ton diesel forklift H3 series model CPCD35-W4H

BINH MINH FORKLIFT COMPANY LIMITED

👉 NORTHERN REGION:

Head office: 3rd floor, Phuc Dong building, Dam Quang Trung Street, Long Bien District, Hanoi.

Warehouse 1: Dai Tu Industrial Park-Hanoi, Phuc Loi Ward, Long Bien District, Hanoi

Warehouse 2: No. 2, TS12 Street, Tien Son Industrial Park, Tien Du District, Bac Ninh Province.

Warehouse 3: Opposite Trang Due Industrial Park, Le Loi Commune, An Duong District, Hai Phong.

👉 CENTRAL REGION:

Office: No. 110, Phan Chu Trinh Street, Doi Cung Ward, Vinh City, Nghe An.

Warehouse: KM04, Vinh Route, Block 2, Vinh Tan Ward, Vinh City, Nghe An.

Office: Lot A4-12 Nguyen Sinh Sac Street, Hoa Minh Ward, Da Nang City.

Warehouse: Lot M1, Road 4A, Lien Chieu Industrial Park, Lien Chieu District, Da Nang City.

👉 SOUTHERN AREA:

Office: 10th Floor, Gia Dinh Building, Hiep Binh Phuoc Ward, Thu Duc City, Ho Chi Minh City.

Warehouse 1: No. 87 Phu Chau, Tam Binh Industrial Park, Tam Binh Ward, Thu Duc City, Ho Chi Minh City.

Warehouse 2: No. 12, Road 2A, Bien Hoa 2 Industrial Park, Bien Hoa City, Dong Nai Province.

Contact: 0987-98-13-15

Email: hodinh777@gmail.com